Implementing New Ideas in a Controlled Way

Also known as the PDCA Cycle, or Deming Cycle

Create a model before you build the final solution.

© iStockphoto/suprun

Something needs to change: Something’s wrong, and needs to be fixed, and you’ve worked hard to create a credible vision of where you want it to be in future. But are you 100% sure that you’re right? And are you absolutely certain that your solution will work perfectly, in every way?

Where the consequences of getting things wrong are significant, it often makes sense to run a well-crafted pilot project. That way if the pilot doesn’t deliver the results you expected, you get the chance to fix and improve things before you fully commit your reputation and resources.

So how do you make sure that you get this right, not just this time but every time? The solution is to have a process that you follow when you need to make a change or solve a problem; A process that will ensure you plan, test and incorporate feedback before you commit to implementation.

A popular tool for doing just this is the Plan-Do-Check-Act Cycle. This is often referred to as the Deming Cycle or the Deming Wheel after its proponent, W Edwards Deming. It is also sometimes called the Shewhart Cycle.

Deming is best known as a pioneer of the quality management approach and for introducing statistical process control techniques for manufacturing to the Japanese, who used them with great success. He believed that a key source of production quality lay in having clearly defined, repeatable processes. And so the PDCA Cycle as an approach to change and problem solving is very much at the heart of Deming’s quality-driven philosophy.

Step 1: Plan

First, identify exactly what your problem is. You may find it useful to use tools like Drill Down , Cause and Effect Diagrams , and the 5 Whys to help you really get to the root of it. Once you’ve done this, it may be appropriate for you to

map the process that is at the root of the problem.

Next, draw together any other information you need that will help you start sketching out solutions.

Step 2: Do

This phase involves several activities:

Generate possible solutions.

Select the best of these solutions, perhaps using techniques like Impact Analysis to scrutinize them.

Implement a pilot project on a small scale basis, with a small group, or in a limited geographical area, or using some other trial design appropriate to the nature of your problem, product or initiative.

Our section on Practical Creativity includes several tools that can help you generate ideas and solutions. Our section on Decision Making includes a number of tools that will help you to choose in a scientific and dispassionate way between the various potential solutions you generate.

Note:

The phrase “Plan Do Check Act” or PDCA is easy to remember, but it’s important you are quite clear exactly what “Do” means. “”Do” means “Try” or “Test”. It does not mean “Implement fully.” Full implementation happens in the “Act” phase.

Step 3: Check

In this phase, you measure how effective the pilot solution has been, and gather together any learnings from it that could make it even better.

Depending on the success of the pilot, the number of areas for improvement you have identified, and the scope of the whole initiative, you may decide to repeat the “Do” and “Check” phases, incorporating your additional improvements.

Once you are finally satisfied that the costs would outweigh the benefits of repeating the Do-Check sub-cycle any more, you can move on to the final phase.

Step 4: Act

Now you implement your solution fully. However, your use of the PDCA Cycle doesn’t necessarily stop there. If you are using the PDCA or Deming Wheel as part of a continuous improvement initiative, you need to loop back to the Plan Phase (Step 1), and seek out further areas for improvement.

When to Use the Deming Cycle

The Deming Cycle provides a useful, controlled problem solving process. It is particularly effective for:

Helping implement Kaizen or Continuous Improvement approaches, when the cycle is repeated again and again as new areas for improvement are sought and solved.

Identifying new solutions and improvement to processes that are repeated frequently. In this situation, you will benefit from extra improvements built in to the process many times over once it is implemented.

Exploring a range of possible new solutions to problems, and trying them out and improving them in a controlled way before selecting one for full implementation.

Avoiding the large scale wastage of resources that comes with full scale implementation of a mediocre or poor solution.

Clearly, use of a Deming Cycle approach is slower and more measured than a straightforward “gung ho” implementation. In true emergency situations, this means that it may not be appropriate (however, it’s easy for people to think that situations are more of an emergency than, in reality, they really are…)

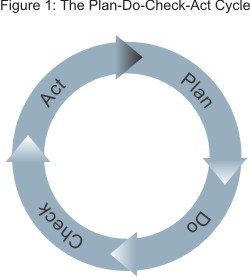

The four phases in the Plan-Do-Check-Act Cycle involve:

- Plan: Identifying and analyzing the problem.

- Do: Developing and testing a potential solution.

- Check: Measuring how effective the test solution was, and analyzing whether it could be improved in any way.

- Act: Implementing the improved solution fully.

These are shown in Figure 1 below.

There can be any number of iterations of the “Do” and “Check” phases, as the solution is refined, retested, re-refined and retested again.

How to Use the Tool

The PDCA Cycle encourages you to be methodical in your approach to problem solving and implementing solutions. Follow the steps below every time to ensure you get the highest quality solution possible.